What we do?

Finishing is done on machine elements (especially heat treated) which are manufactured by machining.

Grinding also has two main points;

- To obtain a clean surface with the desired Ra value on the machine elements.

- Obtain a precise measurement at the desired tolerances.

Processing Properties

Types of Grinding

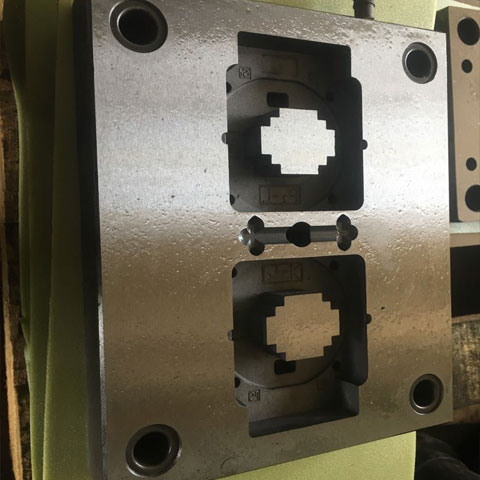

Plane (Surface) Grinding

It is the method used for grinding planar surfaces on the name. In this method, when the stone is rotating, the part is fixed by means of a magnetic table or, in rare cases, a vacuum table. The surface of the workpiece is highest relative to the table, that is, the stone is moved from the nearest point to the stone, and then the grinding process is continued until the entire surface is grinded. Then the part is measured and the main measure is taken and according to this measure the chip is given and the grinding process is continued with the required interval until the required measure. After grinding, it is possible to obtain a glass like surface according to the quality of the stone and the material.

Processing Properties

Types of Grinding

Cylindrical (External) Grinding

It is used to improve the outer surface qualities of workpieces with cylindrical geometry. Unlike plane grinding, cylindrical grinding operations can be performed in any way, including free work between two stones that rotate both as a piece and as a part, or as if it is a partless stone. Just as it is in the case of planar grinding, it is suitable to proceed to the actual grinding process after the basic measurement is taken.

Processing Properties

Types of Grinding

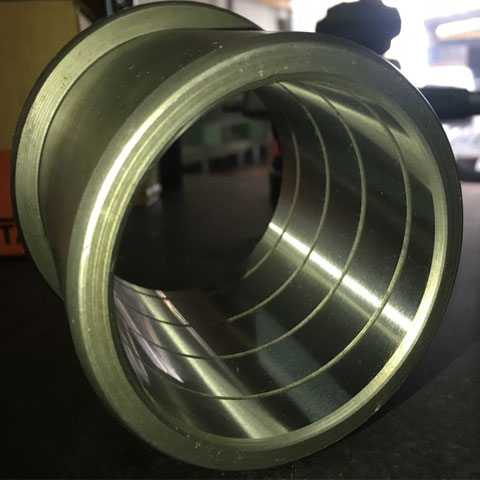

Hole (Internal) Grinding

The inner surfaces are ground so that it is the opposite of the cylindrical grinding. The stone geometries are cylindrical, conical, etc. in accordance with the geometry of the hole to be polished in the shapes. The grinding stone is rotating while the workpiece remains stationary. If precise measurement is desired, it is also necessary to provide sawdust after the actual measurement.

CONTACT US

TEL: 0 262 - 335 44 65

FAX: 0 262 - 335 50 73

About Us

We established in 1996 Ayvaz Makina; cylindrical grinding, hole grinding, surface grinding, disk grinding, machine spare parts manufacturing companies in Turkey are the leading companies.

By following up the developing technology to the highest level technical capacity. By determining the needs of our customers with its experienced staff, we have adopted the principle of fast, reliable and high level technical service.

Today as Ayvaz Makina;

In cylindrical grinding area Diameter 800mm, Length 8500mm, Capacity 10.000 kg,

In the surface grinding area 650mm x 2500mm capacity,

In the disk grinding area, the diameter has reached 1000mm work capacity.

The safety of our staff, the sensitivity you show in the environment will always be our advanced ones.

Our Practice

The value we give to our customers is constant and

we are at your service to significantly improve.

OUR VISION

By winning customer satisfaction, we aim to be a brand in the field of industry and industry in our country and in this way we want to reward our successes with our principles. We do not hesitate to make the necessary investments to bring today's technologies to the next level, and we position our company on these bases. We care about tomorrow today.

Machine Park

UMU

CYLINDRICAL GRINDING MACHINE

OUTDOOR: 320mm

SIZE: 1500mm

UMU

CYLINDRICAL GRINDING MACHINE

OUTDOOR: 320mm

SIZE: 2200mm

STANKO

CYLINDRICAL GRINDING MACHINE

OUTDOOR: 800mm

SIZE: 8300mm

10.000 KG CAPACITY

STANKO

CYLINDRICAL GRINDING MACHINE

OUTDOOR: 600mm

SIZE: 4500mm

FAVRETTO

SUCTION GRINDING MACHINE

MAGNETIC TABLE MEASUREMENT:

650mm X 2500mm

ABA

SUCTION GRINDING MACHINE

MAGNETIC TABLE MEASUREMENT:

300mm X 600mm

ALPA

SUCTION GRINDING MACHINE

MAGNETIC TABLE MEASUREMENT:

600mm X 1600mm

UMU

HOLE GRINDING MACHINE

HOLE DIAMETER:

470mm X 300mm

References